Packaging Manufactures

Food and Beverage Manufactures

Because improper packaging, which does not comply with international standards, can become the cause of problems such as leakage, peeling, tearing, deformation… , it is crucial to control the quality of packaging.

Tensile strength and Elongation

Tensile strength of materials

refers to the maximum stress

(MS) when the specimen breaks,

and elongation refers to the ratio

between the extended length

and the original length.

Peeling Strength

It measures bonding strength between

each layer of laminated films. Due to weak

peeling strength, inter-layer separation

often occurs to laminated films, causing a

series of problems such as mechanical and

permeability property reduction

Puncture Resistance

Measurement of puncture resistance evaluates food packaging’s ability to sustain damages caused by sharp objects.

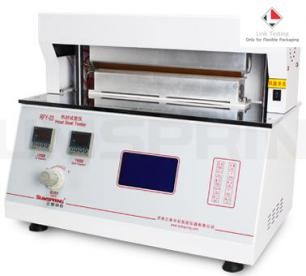

Heat Seal Strength

Heat seal strength refers to the strength at seals after food packaging is sealed under high temperature. Weak heat seal strength causes food leakage, pollution and other problems

Sealability Test / Leak tester

Sealability means the reliability of sealed packaging. Through this test we can assure the completeness of packaging and avoid leakage, pollution, deterioration and other problems due to poor sealability.

Compression resistance of packaging materials

Stacking and pressing is unavoidable during storage and transit of carton packaging, which will affect the packaging properties. By simulating the stacking, pressing, failure and other activities in real use cases, we can quantitatively analyze and evaluate.

Bottle Cap Torque Test

Bottle packaging is one of common packaging forms. The open and close torque of bottle cap is a key technological parameter to be controlled online and offline. It also plays an important role in ensuring safe transportation and good consumer experience.